Turn-Milling Service

Have 5-axis and 6-axis Turn Mill Machines.

Workable OD is 80 mm max. Tolerance could be ±0.005mm.

CNC Turn-Milling Service

Top Level Intl. is proud to share that we have Turn Milling machines. Turn milling machines give us the capability to support you with CNC Turn Milling Service, as we can perform both CNC turning and CNC milling in one operation.

Top Level Intl. has turn-mill machines like TSUGAMI B0205, TSUGAMI B0206 TF III 6, and some 46 type compound turn milling machines. They help us to carry out parts with a workable outside diameter up to 46mm and accuracy down to ±0.005mm.

We can manufacture CNC milled parts based on metals and plastics. For metal raw materials, there are aluminum alloy, copper and copper alloy (brass, bronze), carbon steel, stainless steel, titanium, etc. As to plastics, they could be POM, Nylon, PEEK, ABS, PP, PMMA, Teflon (PTFE, PCTFE), PEI, and so on.

Turn Milled Products

Many people may still not be aware of the advantages of turn milling services. For the detailed advantages of turn-milling machining, please read the article What What are the advantages of Turn-milling machining? in our CNC machining blog.

Please be rest assured that we will offer high-quality CNC parts in fast delivery as required. We also guarantee responsible customer service and after-service. We only promise what we CAN do and try our best to achieve it. Here we promise all customers are always safe by working with us!

What is Turn-Milling Process?

Turn milling is the milling of a curved surface while rotating the workpiece around its center point.

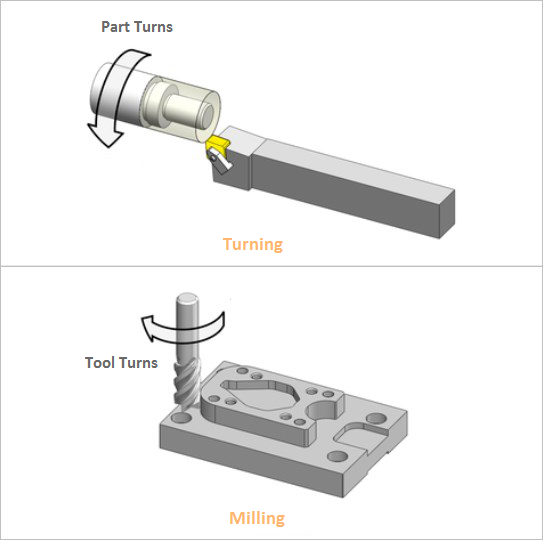

Before coming to Turn-Milling Process, we should first know what turning or milling is. Turning is a machining process in which the workpiece rotates, while the tools of the machine produce the part. Milling is another process in which the workpiece remains stationary, and the tools rotate to produce the custom part. Generally, people performs these two operations on different machines.

However, Turn-mill machines have streamlined the process of CNC machining for us to perform both turning and milling on one machine. So people can do multiple machining processes on just a single machine with only one set-up. This multiple machining is the Turn milling process.

CNC Turn-Mill Machines

CNC turn-mill machines (turn-mill lathes) are multi-function versions of traditional CNC machines. They are advanced combinations of the CNC turning function and CNC milling function. With these advanced CNC machines, even complex workpieces could be produced in a single operation. CNC turn-mill machining is the ideal choice for projects that require a variety of different processes.

Nowadays, parts that require a variety of processes can be machined in just one setup. CNC turn-mill machines can rotate a workpiece incrementally. Such rotating means the machinist can perform the milling operations with rotating tooling in both angular and radial movements.

Email us now! Once you tried our CNC turn-milling services, you will benefit from quick order completion regardless of order volume.

All orders involved would be completed quickly due to the easy set-up and multitasking abilities of the turn-mill machines.