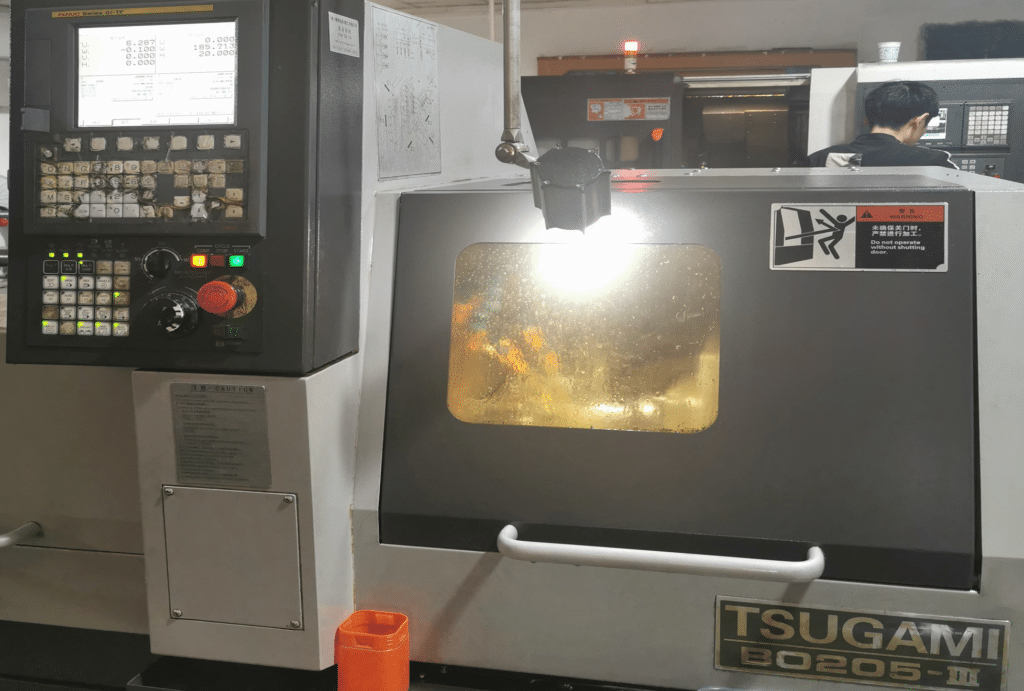

CNC Machining Capabilities

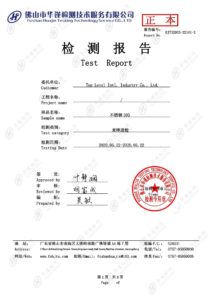

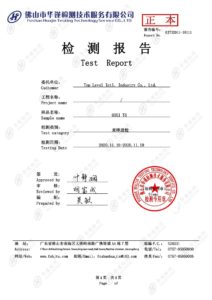

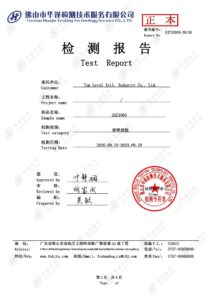

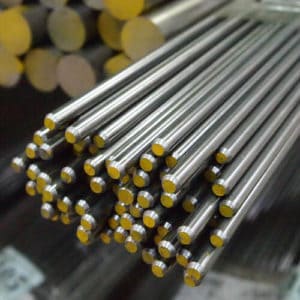

With 15+ years of CNC machining experience, Top Level Intl. now has a full line of CNC processing machines and CNC parts testing equipment. In this page, you will find our CNC machining capabilities on what main CNC machines we have, how we control the quality of custom CNC parts, some certificates and reports, raw materials and surface finishes we can support in your CNC machining items.